Doors

Various doors enrich aesthetic beauty and provide safety to our homes. These doors consist of two parts – frame and shutter. Doors are available in various shapes, designs and materials like wood, iron, PVC or plastic and aluminium in the market. This Pinnacle Construction help article tells you about various types of doors in detail.

Wooden Doors

Wooden doors are used in our homes traditionally. They are attractive, durable and provide safety to homes. These doors are easy to make and are preferred for their carved designs. Easy availability of timber and attractive look make them superior to other doors. Wooden doors are available in following categories in the market.

1. Flush Doors

2. Panelled Doors

a. Semi Solid Doors

b. Solid Wood Door

3. Wire Gauge Doors

1. Flush Doors

These doors are becoming popular for their nice look, less cost and better strength than panelled doors. Flush doors are easy to make and undergo little expansion or contraction with the changes in weather.

Now flush type doors has gained a major market share in the construction of a house. It has plain or curved facings on both sides of the construction. A flush door consists of skeleton or a hollow framework of rails and stiles, top and bottom rails, and narrow intermediate rails. It is covered on each side by a sheet of plywood. This door has a joint-less surface on both the sides.

The shape stability of this door depends to an extent on the fixing on the flush or moulded facing to the core. The lighter and thinner the core the more facing are used to provide stability. The nominal thickness of flush door shutter varies from 25mm to 40mm depending upon the types of doors.

Decorative type plywood or face veneer is used for the face panel that is called a decorative type of door. Decorative plywood shall be bonded with a synthetic resin adhesive, borer proof suitable for intended use. Decorative veneer may be rotary cut or sliced which is usually not more than 1 mm thick.

Non-decorative type plywood or face veneer is used for the face panel that is called a non-decorative type of door.

Advantages of Flush Doors:

1. Good uniform strength

Plywood is a strong material, it gives your door a uniform wooden look with consistent beauty. These are low maintenance durable doors.

2. Available in large sizes compared to solid wood

It’s very easy to get a nice looking uniformly thick plywood sheet of size 7’x3.5′ (7 feet x 3.5 feet) from the market, but quite impractical to get solid flat wood of such a size (which tree could be cut and how?). This is the most significant benefit that plywood offers compared to solid wood, and that’s the reason it became so popular since its discovery. These large sized engineered plywood sheets allow for a variety of applications that would be difficult to achieve using solid wood.

3. Economical use of wood by mixing various woods together

Some woods are priced for their beauty (teak, diyar, mahogany, ash, oak etc.) but are also costly. The grains of such woods can be achieved to form the surface layer of the plywood, while the inner layers could be composed of other strong but cheaper woods. Such a mix and match is possible while constructing plywood and the financial benefits accrued from this, can be passed on to the end consumer.

4. Available in varieties such as flexible plywood several interesting varieties have now come up in plywood. One of them is flexible plywood (also known as bendy ply). It can be rolled up or bent to form curved surfaces and allows for more applications curved/circular doors.

5. Lesser wastage of wood in comparison with the process of acquiring solid wood blocks, the plywood making process has less wastage of material, so we can utilize more part of the tree logs in this way.

6. Durable material Plywood is quite durable and lasts many long years. Not as long as solid wood pieces, but much better compared to the cheaper Particle board/solid core semi solid doors, which eventually needs to be replaced.

7. Less costly compared to solid wood Solid wood is better, because it is a natural product, but it’s also very costly. Plywood costs lesser in comparison. So a reasonable trade-off for most people is to opt for decent quality plydoors

Disadvantages of Flush Doors:

1. Water can damage plywood. The layers of plywood can come apart on prolonged exposure to water. This drawback can be overcome by choosing BWR Waterproof grade for plywood that is likely to get wet.

2. Difficult to judge the quality of a plywood sheet. As a customer, it’s difficult to judge which wood has been used for making the plywood. The outer surface veneers can be seen, but what about the inner ones? The market has several varieties of plywood, from locally made products to those from reputed brands. Its important to choose wisely and buy from a trusted source.

3. Not considered as strong as solid wood. Plywood is not as strong as the heavier and denser as solid wood. However the plus point is that plywood costs lesser.

2. Paneled Doors

Paneled doors consist of a frame grooved inside edges to receive one or more panels. Vertical members are called as stile whereas horizontal members are called rail i.e. top rail, middle or lock rail, and bottom rail etc. The door may have two to ten panels according to drawing or architectural requirements. The panels are made of timber, plywood, lasani board, veneered particle board etc. All members of shutters should be straight without any wrap bow and should have smooth well planned face at right angles to each other.

Timber for stiles and rails of paneled doors should be of same species from seasoned wood. The timber should be plane, smooth and accurate to the required dimensions. Using mortise and tenon joints, stiles and rails should be jointed. The contact surfaces of joints should be treated with bulk type synthetic resin adhesive and pinned with 10 mm dia. The thickness of door shutters varies from 25 mm to 40 mm.

Semi Solid Doors

Solid cores used in semi solid are made from pressed panels of lasani sheets or sawdust or scrap wood binded with a resinous adhesive. Solid cores are also made from small blocks of wood joined together with glue

Semi-solid doors are available in many of the same varieties as hollow or solid doors. They feature many different wood species and grain matches, as well as a large selection of paints and polish. These doors can be pressed with panel designs or can be cut to receive windows or louvers. Most semi-solid doors still have solid lumber edges to improve security and help hold locks and hardware in place.

Advantages of Semi Solid Doors

• The doors are comparatively heat resistant

• The doors can resist abrasions

• The colours on the door remain vibrant and bright for a long time

• They are eco-friendly as tree wood is not wasted. All wasted wood chips, sawdust, tiny wasted pieces of wood effectively used in semi solid doors.

Disadvantages of semi solid doors

2. Many semi solid doors have lower grades or cuts of wood. You will often find that the very cheap engineered woods. The graining looks different and cheaper than what you are expecting on solid wood door. Also, some cheaper engineered doors has a lot of “shorts” (i.e. pieces that are only few inches in length which are glued together). Some of them will have more knots, too. This is something that is not apparent in the samples.

2. Life of semi solid doors is not very long. Tiny wood parts or Lasani sheet inserted in doors will lose joint in longer run. Cost cutting and lower craftsmanship result in improper pressing and poor gluing.

3. There is excessive use of adhesives in semi solid doors. Adhesives used in some doors may be toxic. A concern with some resins is the release of formaldehyde in the finished product, often seen with urea-formaldehyde bonded products.

4. Most workshop owner don’t obey industry standards for making solid core/engineered wood. Workers use unauthentic shortcuts to make the job done.

5. Some semi solid doors look and sound more fake, it will sound and look more artificial. If your house is for sale, it may cause some buyers may feel this is a lower value.

Solid Doors

Wood doors have a rich sense of character and beauty all their own. Perhaps this can be attributed to their natural wood grain, their polished appearance and the heavy, durable feel they tend to have. What’s more, they can be a stunning way to make a statement at your front entry and also give guests an idea of what awaits in your home’s interior spaces. Here are a few features of wood doors to note before installing one at your home.

All of woods that go in to doors are hand selected from rough cut whole wood to ensure that you receive matching grains of wood on all of the components of your doors. Both our exterior wood doors and interior wood doors are ensured to be the highest quality due to their hand-crafted construction, deep pocket mortise and tenon joinery, feather tenoned and double tongued base rails, floating panel frames, secure seated louvers, full custom thickness and sizing, historically accurate designs and styles.

Pros

As noted above the wood grain is one of the most attractive features of a wooden exterior door. As with wooden doors, there are numerous options of wood to choose from when it comes to your door. You can have everything from a modern and Ash or Mahogany to a traditional Diyar or Kyle along with plenty of selections that fall somewhere in between. Door panels, molding and any special feature you want can be crafted into the wood. You can also customize the finish of your door with polish or paint. Polish is a popular choice allowing you to show the wood’s natural grain.

Solid wood doors means you have superior durability and insulation. This may not only help with security concerns and energy savings, but could also reduce the amount of noise you hear from the outdoors.

Another attractive quality of wood doors is that they can be custom made to fit any size opening or trimmed to a specific size doorway. In this regard, wood is a material that easy to work with and can be made to fit your exact needs. You can even have windows or space for glass inserts cut into a custom door.

Cons

Cost; it is biggest disadvantage of Solid wood doors. Solid wood doors not only looks expensive but they are actually very expensive. Solid wood doors cost significantly high due to the fact that they are made completely from wood.

Wood doors do require a bit of care and maintenance to keep them looking and performing at their peak. For instance, you may need to touch up polish or paint every few years, as they may chip with normal wear and tear over time.

One other thing to note is that wood doors — because of their heavy material — may sag over time. Again, this can be fixed with routine maintenance or updates to your hardware and frame.

d) Wire Gauge Doors

Wire gauge or fly proof door shutters are fixed to provide free air circulation and prevent mosquitoes, flies, insects etc. from entering into the building. Wire gauge or fly proof doors are generally provided in kitchens, canteens and refreshment rooms. The external doorframe has double rebate having panel door shutter open inside whereas outer shutter is of wire gauge and open outside.

Manufacturing of wire gauge doors is almost same as panelled doors; the only difference is of wire gauge in panels used instead of wood or ply panels. Wire gauge in panel should have single piece and each panel should not exceed 0.5 sq. meters.

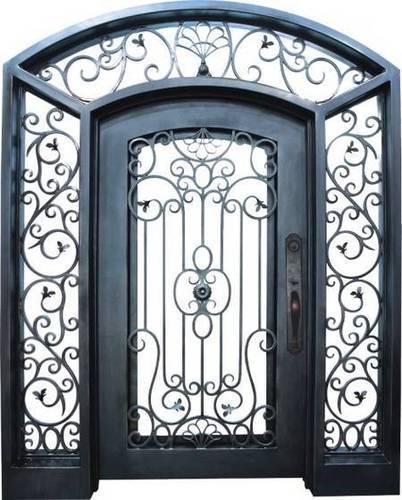

Iron or Steel Doors

Rolling shutters are used for main door entry of shops, commercial complex and garage in houses. M.S. angles, T- Iron and square bars iron doors are provided at entry gate of the house. Steel doors are extremely durable and can also be painted in polished look. The only drawback of these doors is that they easily corrode and discolour.

PVC or plastic doors

PVC or plastic doors are mostly used in toilets and remain unaffected from water and termite effects etc. They are available in wide range of colors and required sizes. PVC doors are anti corrosive, light weight and maintenance free. They are manufactured in plastic factories. Plastic doors are resistant to moisture and chemical but they cannot resist harsh environment conditions like wooden or metal doors. These doors are not suitable for entry doors as they are combustible in nature, hence they should be saved from fire.

Aluminium doors

Aluminium doors are used typically in shower cabins, shops, departmental stores, hotels and commercial establishments. In official and residential buildings, aluminium doors are used to offer architectural considerations between formal and informal areas. They are durable and prevent unwanted intrusions. Aluminium doors are good choices for houses with modern designs. These doors do not rust, provide weatherproof qualities but they can be water stained easily and look white due to oxidation.